The Evolution of the Zarum Guitar

Where heritage becomes craft, and craft becomes sound.

Before instruments, there was The Art of Zarum: a studio practice grounded in restraint, balance, and deep attention to form. Each artwork explores tension, rhythm, and negative space—how intention shapes presence, and how material responds when it is listened to rather than forced. Nothing is added without purpose. Nothing remains without meaning.

Alongside the art studio exists a large, fully equipped woodworking shop. Years of working with wood—studying grain, stiffness, movement, and structure—inform every decision made at the bench. This understanding of material is not separate from the artwork; it is its physical extension.

Music has always been the third pillar.

As a guitarist and vocalist, and as someone raised among professional musicians and flamenco guitarists, sound has never been abstract. Flamenco was not discovered—it was present. Rhythm, compás, attack, and expression were absorbed long before they were analyzed. This musical heritage forms an unspoken foundation beneath every Zarum guitar.

The instrument is born at the intersection of these three disciplines:

art, woodworking, and music.

Classical and flamenco traditions provide the structural language—Spanish construction methods, established proportions, and performance-driven requirements. These traditions are approached with respect, but never rigidity. They function as frameworks, much like a musical form or a visual composition, within which personal voice and evolution can occur.

From there, each guitar is built and composed simultaneously.

Voicing a top is both a technical and musical act—carving, thinning, and shaping until the wood responds with clarity and balance. Bracing patterns guide tension and release, much like phrasing in music or structure in visual form. Flamenco guitars are built for immediacy, percussive response, and controlled bite. Classical guitars are voiced for depth, sustain, and dynamic nuance.

Each instrument is made slowly, by hand, using traditional techniques within a fully capable modern workshop. The process allows for listening—tapping, flexing, adjusting—until the guitar reveals how it wants to speak. This dialogue between maker, material, and sound mirrors both the evolution of a work of art and the interpretation of a piece of music.

No two Zarum guitars are identical. Each reflects the character of the wood, the lineage it comes from, and the player it is built for. What remains constant is the philosophy: craft without excess, tradition without stagnation, and expression rooted in lived experience.

The result is an instrument that carries flamenco heritage, musical understanding, and visual discipline in equal measure—rooted in tradition, yet unmistakably personal.

This is the evolution of the Zarum guitar:

Where heritage becomes craft, and craft becomes sound.

Guitar neck head showing the cutaway design at the top which is unique to Zarum guitars

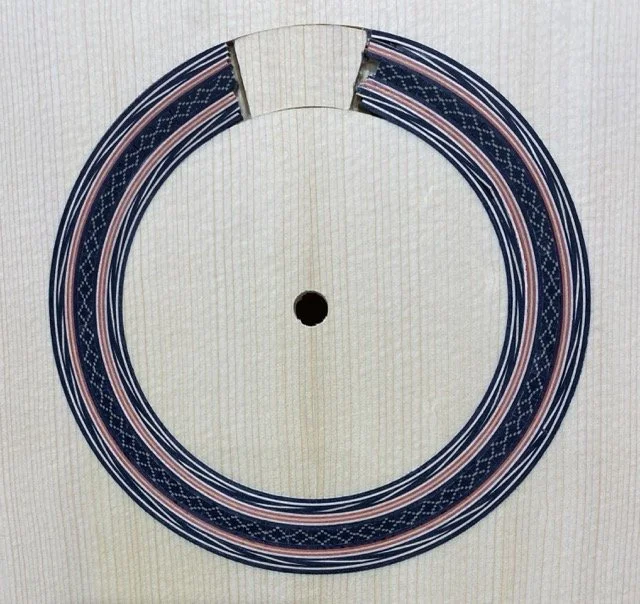

A completed rosette around the sound hole of the guitar which has not yet been cut out.

The guitar SOLERA which is the mould in which the guitar is assembled. shown behind is a shelf with some tone woods.

The sides of the guitar being places inside the SOLERA

The back of the head showing the tuners

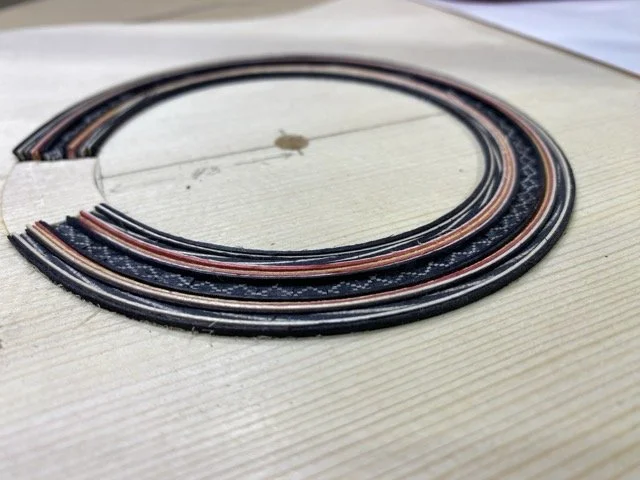

The rosette being assembled. You can see the .5mm wood veneers used in its construction.

The sides of the guitar before being bent to shape. Shown here is Indian Rosewood.

The sides of the guitar being places inside the SOLERA

The soundboard made of European Spruce with the completed rosette before the sound hole is cut out.

The pattern used to place the harmonic bars

The back braces being glued to the back of the guitar

The soundboard with the rosette channel cut out

The completed back of the guitar with the support bars

Harmonic bars being glued to the soundboard

Harmonic bars being glued to the soundboard

The interior of the soundboard is complete.

The SOLERA without the sides attached

A guitar just out of the SOLERA is hung on the shelf containing tonewoods

A Zarum Classical guitar in the process of french polish

A Zarum Classical guitar in its hardshell case

A Zarum Classical guitar in the process of french polish

A Zarum Classical guitar in the process of french polish

Cliose up of the rosette showing the tiny .5mm pieces of wood veneer used in its construction

A completed Zarum guitar showing the Zarum label seen through the sound hole

A Zarum Flamenco guitar with Curly Maple back and sides

A Zarum Classical guitar with Walnut sides and back

A Zarum Classical guitar with Walnut sides and back

A Zarum Classical guitar with Walnut sides and back

A Zarum Classical guitar with Walnut sides and back with a Zarum Flamenco Blanca guitar behind it.

A Zarum Flamenco guitar with Curly Maple back and sides

A Zarum Flamenco guitar with Curly Maple back and sides

A Zarum Flamenco guitar with Curly Maple back and sides and a Zarum Classical guitar with Walnut back and sides behind it

A Zarum Flamenco Blanca guitar with Mediterranean Cypress back and sides

A Zarum Flamenco guitar with Curly Maple back and sides and a Zarum Classical guitar with Walnut back and sides behind it

A Zarum Flamenco guitar with Curly Maple back and sides and a Zarum Classical guitar with Walnut back and sides behind it